Critical Minerals & Materials

Critical minerals are the building blocks of modern technology, national security, and clean energy systems - yet, they are often in limited supply or concentrated in a few regions.

- Overview

- Technology Gaps

- Roadmaps & Resources

- Conferences

What are Critical Minerals and Materials?

The Energy Act of 2020 defines a “critical mineral” as:

Any non-fuel mineral, element, substance, or material that the Secretary of Energy determines: (i) has a high risk of supply chain disruption; and (ii) serves an essential function in one or more energy technologies, including technologies that produce, transmit, store, and conserve energy; or

A critical mineral, as defined by the Secretary of the Interior.

The Secretary of Energy determines the Critical Materials List, which includes materials for energy as well as critical minerals:

- Aluminum

- Cobalt

- Copper

- Dysprosium

- Electrical Steel

- Fluorine

- Gallium

- Iridium

- Lithium

- Magnesium

- Metallurgical Coal for Steelmaking (including Anthracite)

- Natural Graphite

- Neodymium

- Nickel

- Platinum

- Praseodymium

- Silicon

- Silicon Carbide

- Terbium

Critical Minerals

Critical minerals includes the following 50 minerals: Aluminum, antimony, arsenic, barite, beryllium, bismuth, cerium, cesium, chromium, cobalt, dysprosium, erbium, europium, fluorspar, gadolinium, gallium, germanium, graphite, hafnium, holmium, indium, iridium, lanthanum, lithium, lutetium, magnesium, manganese, neodymium, nickel, niobium, palladium, platinum, praseodymium, rhodium, rubidium, ruthenium, samarium, scandium, tantalum, tellurium, terbium, thulium, tin, titanium, tungsten, vanadium, ytterbium, yttrium, zinc, and zirconium.

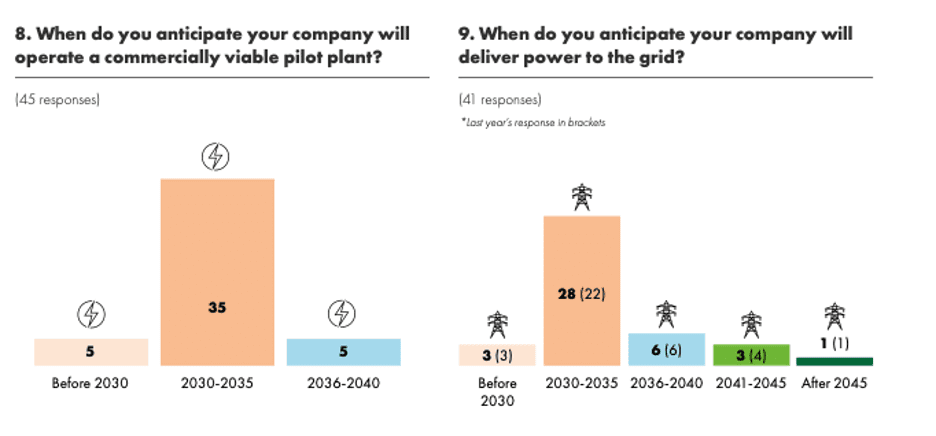

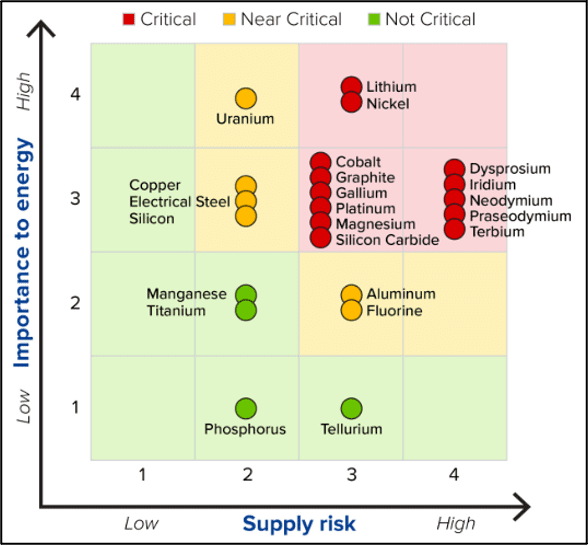

The Department of Energy published the following medium-term (2025–2035) criticality matrix:

Source: U.S. Department of Energy

Why are they critical?

Critical minerals are the building blocks of modern technology, national security, and clean energy systems – yet, they are often in limited supply or concentrated in a few regions, creating vulnerability in global supply chains.

National Security: Many defense systems, including jets, missiles, satellites, and communications gear, rely on critical minerals such as rare earth elements, titanium, and beryllium for performance and durability. Secure access to these materials is vital for military readiness and technological superiority.

Clean Energy Transition: Critical minerals like lithium, cobalt, nickel, and rare earths are essential for batteries, wind turbines, solar panels, and electric vehicles.

Economic Competitiveness: Nations that can produce, process, or recycle critical minerals gain strategic economic leverage while avoiding dependence on imports.

Technological Innovation: Smartphones, semiconductors, advanced sensors, and other high-tech products depend on critical minerals because their unique properties enable smaller, faster, and more efficient devices.

Supply Chain Resilience: Because extraction and refining are often geographically concentrated, supply disruptions can ripple through entire industries — from automotive to defense to energy.

Technology Gaps

Extraction and Processing

Technology gaps for rare earth elements (REEs) contribute to vulnerabilities in the global supply chain, and exist from the extraction phase through their processing and recycling. The development of alternative materials is also considered a technology gap.

Separating REEs from one another is a complex, high-energy, costly process – due to their having such similar chemical properties. Traditional REE processing uses vast amounts of toxic chemicals, and the process often generates radioactive and hazardous waste.

Promising new extraction and separation methods exist at the laboratory scale and primarily include the use of solvents or supercritical CO2. Bio-based extraction, including biomining with microbes, is also a potential approach under development. While ongoing research utilizing these methods focuses on safer, more sustainable alternatives to traditional processes, the technology for large-scale, cost-effective, and environmentally friendly production is not yet scalable.

Recycling

Many REE recycling processes are not economically feasible. In fact, recycling REEs from end-of-life products can actually be more expensive than mining for raw material, due to the low concentration of REEs in most consumer devices. Because REEs are used in such miniscule amounts that are closely integrated into complex electronic and magnet components, extracting them requires manual disassembly, which is highly labor-intensive and time-consuming.

Current recycling technologies use high heat and/or harsh chemicals, which are inefficient and can be harmful to the environment. Technology gaps for recycling include the need for more advanced sorting and molecular separation techniques.

Other Gaps

REE refining also faces gaps in technical expertise and the specialized infrastructure it requires. Currently, even if REEs are mined in the U.S., the raw material is often sent overseas for processing.

Roadmaps and Resources

Critical Minerals & Materials: U.S. Department of Energy’s Strategy to Support Domestic Critical Mineral and Material Supply Chains (FY 2021–FY 2031)

Critical Materials Collaborative (CMC): Forming Connections Across the Critical Materials Innovation Ecosystem (September 2025)

https://www.energy.gov/sites/default/files/2025-09/critical-materials-collaborative-factsheet.pdf

Critical Materials Collaborative (CMC): Forming Connections Across the Critical Materials Innovation Ecosystem (September 2025)

https://www.energy.gov/sites/default/files/2025-09/critical-materials-collaborative-factsheet.pdf

The U.S. Department of Energy’s Critical Minerals and Materials Program: Building Secure Supply Chains for America’s Energy Future (January 2025)

Critical Materials Innovation Hub: 10 Years of Innovation, Influence, & Impact (December 2024)

https://www.energy.gov/sites/default/files/2024-12/cmi-hub-10-year-retrospective.pdf

2023 DOE Critical Materials Assessment (July 2023)

https://www.energy.gov/sites/default/files/2023-07/doe-critical-material-assessment_07312023.pdf

Critical Materials Rare Earths Supply Chain (April 2020)

https://www.energy.gov/eere/amo/articles/critical-materials-supply-chain-white-paper-april-2020

Conferences and upcoming major events

Rare Earth Mines, Magnets & Motors 2025: September 23-24, 2025 – Toronto, Canada

International Commodity Summit 2025: November 17-20, 2025 – Cape Town, South Africa

https://internationalcommoditysummit.com/

MSIT Seminar on Rare-Earth Materials & Magnet Technology: November 18-19, 2025 – Stuttgart, Germany

https://www.msiport.com/msit-events/seminar-on-magnet-technology/seminar-2025/

SME Annual Conference & Expo (MINEXCHANGE 2026): February 22-25, 2026 – Salt Lake City, Utah

Project Blue Critical Materials Conference: EV & Battery: February 24-25, 2026 – Berlin, Germany

https://projectblue.com/events/39/critical-materials-conference:–ev-&-battery

PDAC 2026 – The World’s Premier Mineral Exploration & Mining Convention:

March 1-4, 2026 – Toronto, Canada https://pdac.ca/convention-2026

Critical Minerals North America Conference and Exhibition: April 23-26, 2026 – New York, New York

Critical Minerals Conference: September 20-23, 2026 – Brisbane, Australia

Explore Other Energy Sources

Stay in the Know with Dawnbreaker®

Receive valuable industry insights such as our Market Snapshots, SBIR/STTR & TABA updates, & webinar announcements.