Algae encompass a diverse group of organisms, including both macroalgae, such as kelp and nori, and microalgae, like spirulina and chlorella. Over 50,000 species of algae have been identified world-wide. All types of algae possess chlorophyll and play a crucial role in aquatic ecosystems, serving as the primary source of energy for aquatic organisms. The U.S. government has exhibited an interest in using algae for both nutrition/animal feed applications and for biofuels/bioproducts. In its most recent solicitation, the U.S. Department of Agriculture (USDA) sought novel or innovative approaches for algal production systems to improve quality, development, and harvesting of algal biomass for use in aquaculture feed and human food. The main cultivation systems widely used for algae cultivation are open ponds, attached growth systems, and closed photobioreactors (PBRs).

The aquaculture industry has demonstrated a growing interest in cultivating microalgae because of its rapid growth and high lipids content. Algae products like lipids (omega-3, omega-6, and omega-9), carotenoids, carrageenan, agar, algal protein, algal flour, and alginate can be extracted from algae to serve various end-use applications. Applications in the algae products market include food & beverages, nutraceuticals & dietary supplements, animal feed, pharmaceuticals, personal care products, and other applications.

The algae-based animal feed market is one part of the algae products market. The algae-based animal feed market is expected to grow to $6.6 billion by 2034 from the 2024 valuation of $4.5 billion, exhibiting a CAGR of 3.9%. This market includes microalgae and macroalgae for both animal feed and aquaculture feed products. The use of algae in animal and fish feed is becoming increasingly popular. By type and source, aquaculture and microalgae hold the dominant share of the market respectively. Over half of the fish on the market are raised in fish farms, where fish feed constitutes around 90% of the cost. Most of the fish feed currently used is derived from either wild fish or terrestrial agricultural products. Both sources present problems in sourcing. Microalgae biomass, on the other hand, has the potential to support sustainable aquaculture and a circular economy as an environmentally-friendly feed ingredient. However, the high cost of microalgae production remains a barrier to aquaculture.

While algal biomass cultivation has significant market potential, especially as seen for fish feed, the USDA is searching for improved production systems. The main cultivation systems—open ponds, attached growth systems[1], and photobioreactors (PBRs)—have their own shortcomings and challenges. General barriers for mass cultivation include financial challenges (the cost of water and nutrients) the limitations on recycling, biomass loss due to biocontamination and pond crashes, as well as the energy costs associated with harvesting. While open ponds have lower capital costs, they yield lower overall production rates. A major challenge of open ponds is the sensitivity to pollutants. Thus, only a few species can be cultivated in these ponds for biomass production on a commercial scale. Another concern is the problem of evaporation in open systems, which require water replacement to maintain the optimum balance of suspended salts and water.

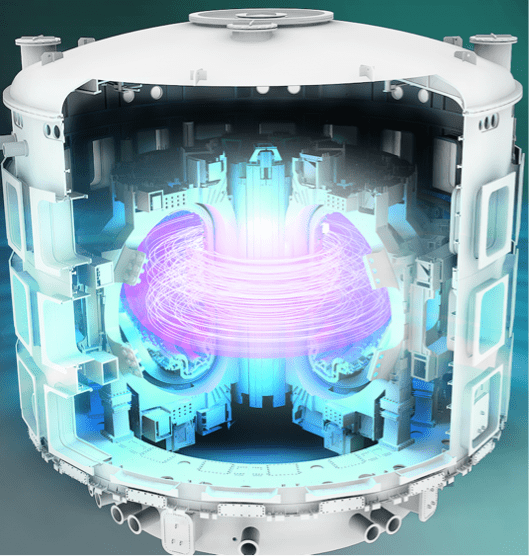

Enclosed photobioreactors offer several advantages over open systems, which include larger surface-to-volume ratio, reduced risk of contamination, smaller area requirements, and the ability to prevent evaporation. Vertical-column and tubular photobioreactors designs are the most used. However, photobioreactors are more costly: the construction and maintenance are ten times higher than open ponds. While photobioreactors can maintain higher biomass density, the significant cost difference makes photobioreactors uncompetitive for industrial-scale production of microalgae biomass. As a result, closed system photobioreactors are mainly used for higher value products. The development of new technologies, such as closed-loop photobioreactors and precision fermentation, are improving the cost effectiveness of algae biomass production. Such advances seek to address the concerns related to high production costs, but microalgae harvesting remains a challenge for commercial-scale biomass production.

Improved algal production systems would benefit various markets and industries beyond aquaculture, including biofuels/bioproducts, pharmaceuticals, and wastewater treatment. The U.S. Department of Energy’s (DOE) Bioenergy Technologies Office (BETO) has an Advanced Algal Systems program, which supports research and development (R&D) to lower the costs of producing algal biofuels and bioproducts. The Algae Biomass Organization (ABO) explains how algae-based systems have the opportunity to provide a sustainable solution to wastewater treatment, identifying Iowa-based Gross-Wen Technologies’ patented solution Revolving Algal Biofilm (RAB) treatment system, which utilizes an algae biofilm to treat wastewater.

[1] Open ponds and photobioreactors are the two systems predominantly used for algae growth related to animal and fish feed. Attached growth systems relate to algal biomass production for biofuel and wastewater treatment.